Description

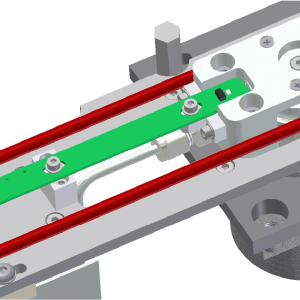

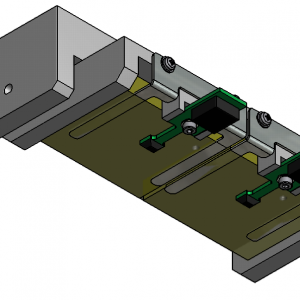

The Jade Pro is a handload system, incorporating a universally adjustable tooling carrier capable of accommodating PCBs or pallets up to 457mm x 508mm.

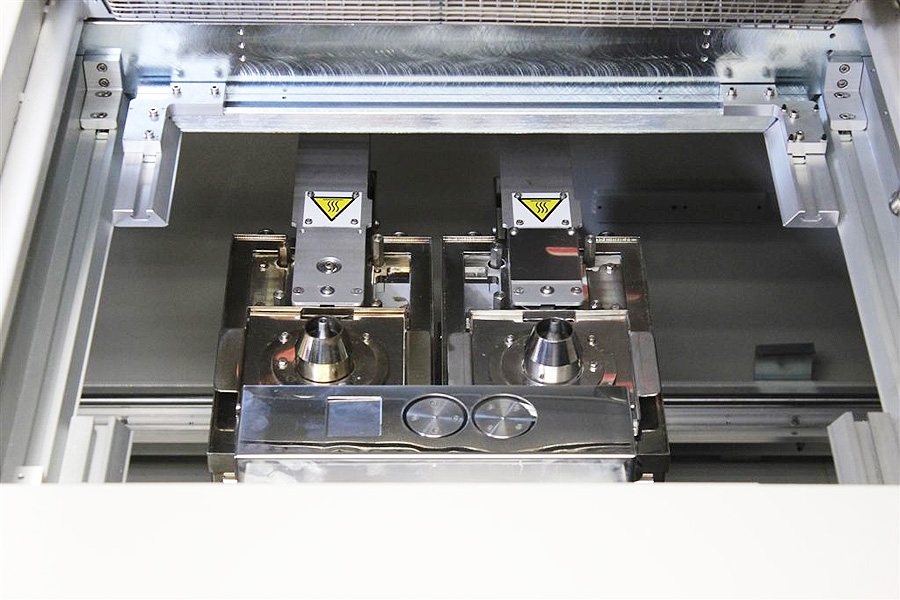

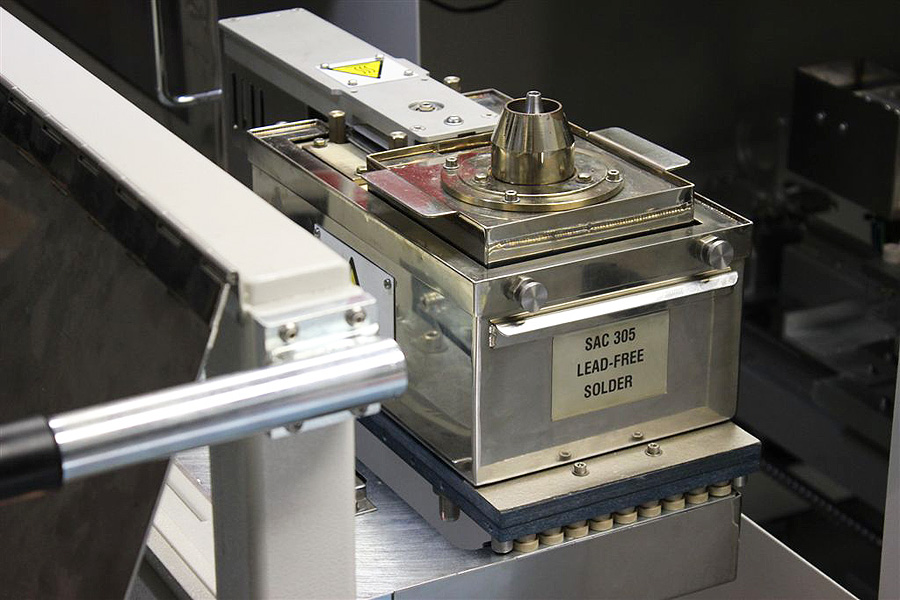

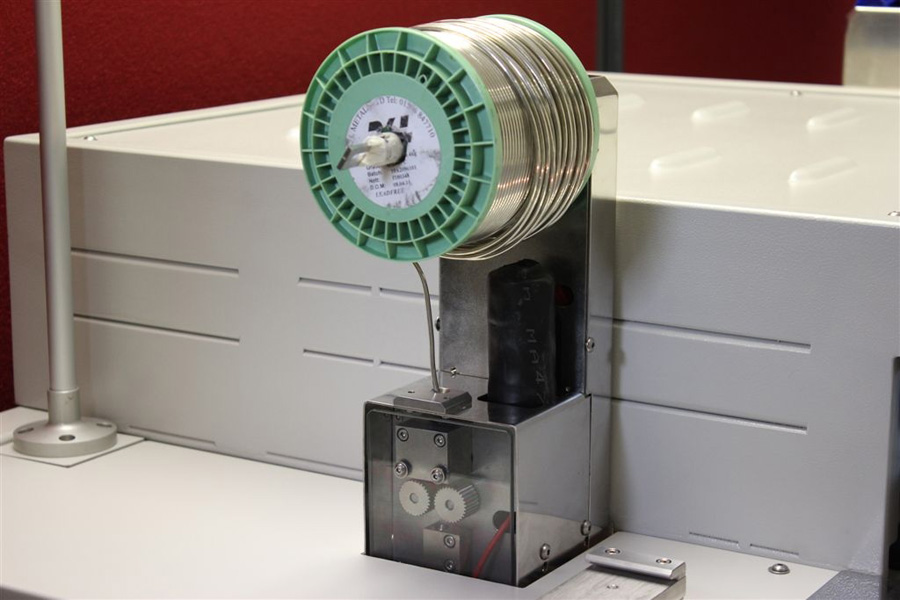

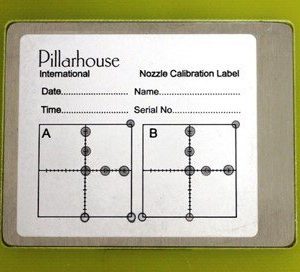

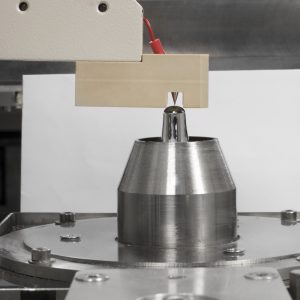

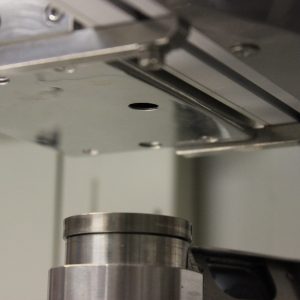

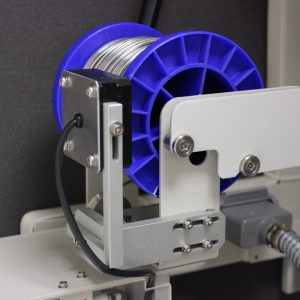

As standard, the Jade Pro is configured with our Duplex twin solder bath arrangement. This twin independent Z axis solder bath arrangement offers increased production flexibility by permitting use of two different nozzle tip sizes within any single process programme, which can be allocated as process requirements dictate within any particular area on a PCB. Alternatively, different solder alloys can be utilised within this single machine setup.

The Jade Pro series is controlled by a PC, through PillarCOMM, a Windows® based ‘Point & Click’ interface with a PCB image display.

Additionally, our PillarPAD offline programming package allows the operator to produce programs independently from the machine using Gerber data.

For visual information about our Jade Pro, please visit our YouTube channel’s video here: Pillarhouse Jade Pro Series – YouTube

For more information about Pillarhouse International’s other handload selective soldering systems, please visit: Selective Soldering – Handload – Pillarhouse International