Description

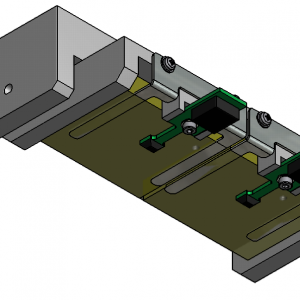

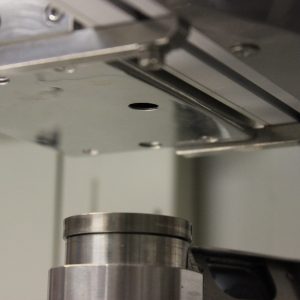

The standard Orissa Synchrodex Pro solder module is supplied with an on-board Drop-Jet flux head and offers top side and bottom side slide in/out infra-red pre-heat linked to closed-loop pyrometer control. Pillarhouse can also configure any of our frame sizes to operate as dedicated fluxing and/or I.R./convection heating modules, which, when placed in-line with solder module(s), will significantly increase production throughput.

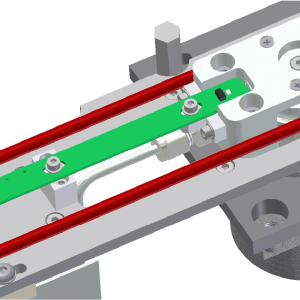

Our 1600mm solder module offers the ability to process PCBs using either a single or dual-bath operating format. Single bath operation allows for an alternate nozzle process on a single 610mm x 610mm PCB. Dual-bath operation allows for a dual-board, simultaneous, independent nozzle process for increased soldering flexibility on 420mm x 610mm PCBs. Pillarhouse’s uniquely flexible approach is facilitated via a software controlled, mechanical three pin stop arrangement on the conveyor section allowing for either single or dual PCB management.

Our largest PCB handling capability of 1143mm x 610mm can be achieved when using the XL frame size.

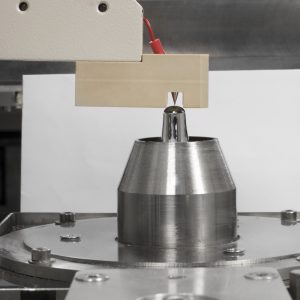

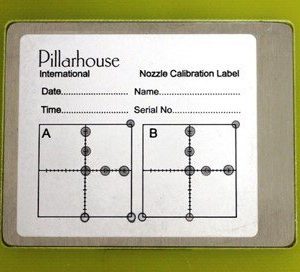

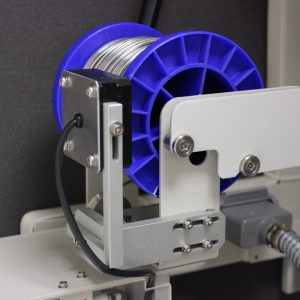

The Orissa Synchrodex Pro can be configured with any of the currently available Pillarhouse solder technologies, including single point AP-1, patented 1.5mm micronozzle, Jet-Wave and custom multi-dip. Easy, rapid non-contact solder pot changeover is facilitated via the optional heated pot exchange trolley.

The Synchrodex Pro is controlled by a PC through our next generation PillarCOMM.NET, a Windows® based ‘Point & Click’ interface with PCB image display. Additionally, PillarCOMM.NET has an offline package that allows the operator to produce programs independently from the machine using Gerber data.

For visual information about our Synchrodex Pro, please visit our YouTube channel’s video here: Orissa Synchrodex Pro Machine Animation – YouTube

For more information about Pillarhouse International’s other in-line selective soldering systems, please visit: Selective Soldering – In-Line – Pillarhouse International