Description

The Orissa Fusion is available in two frame sizes.

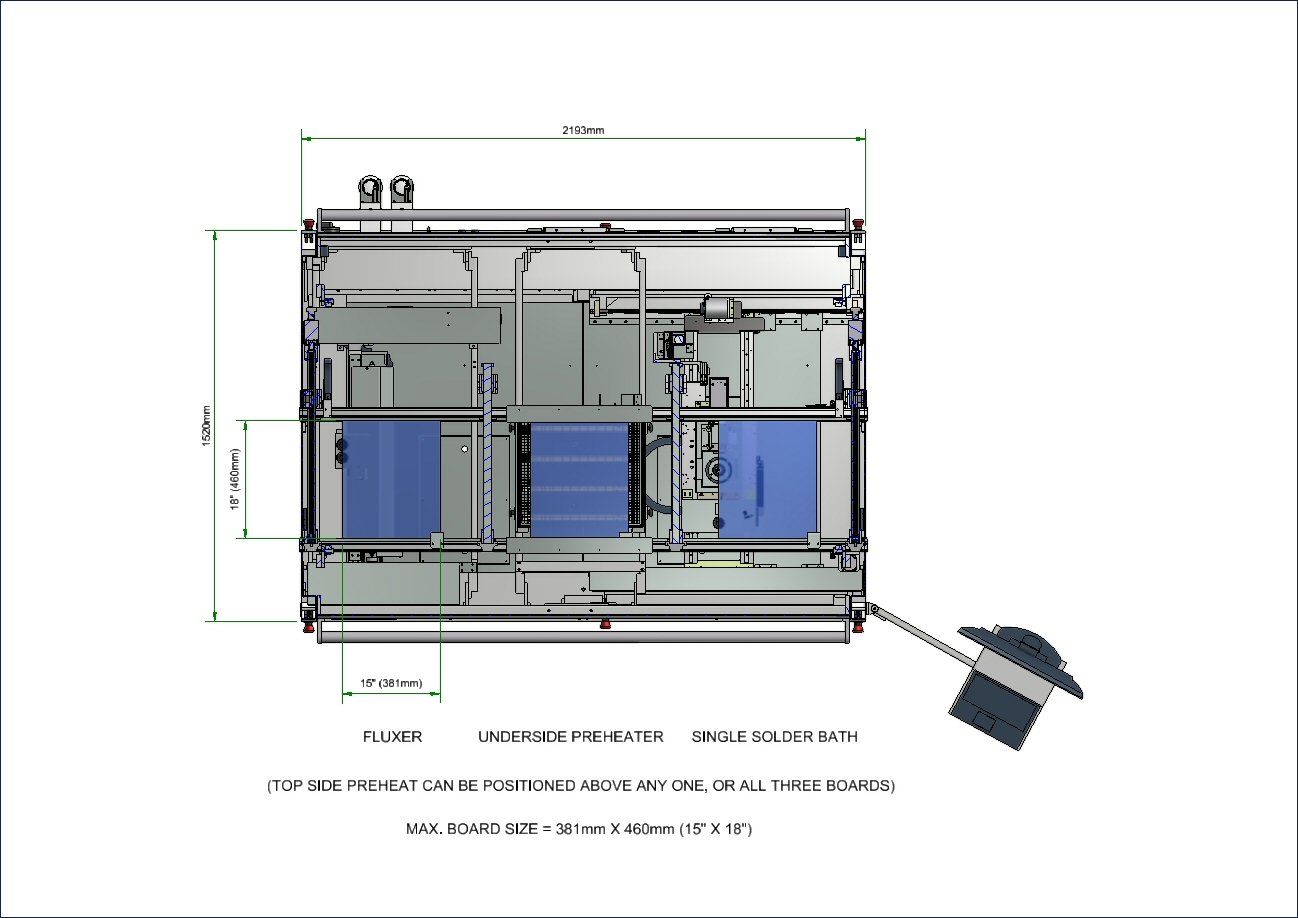

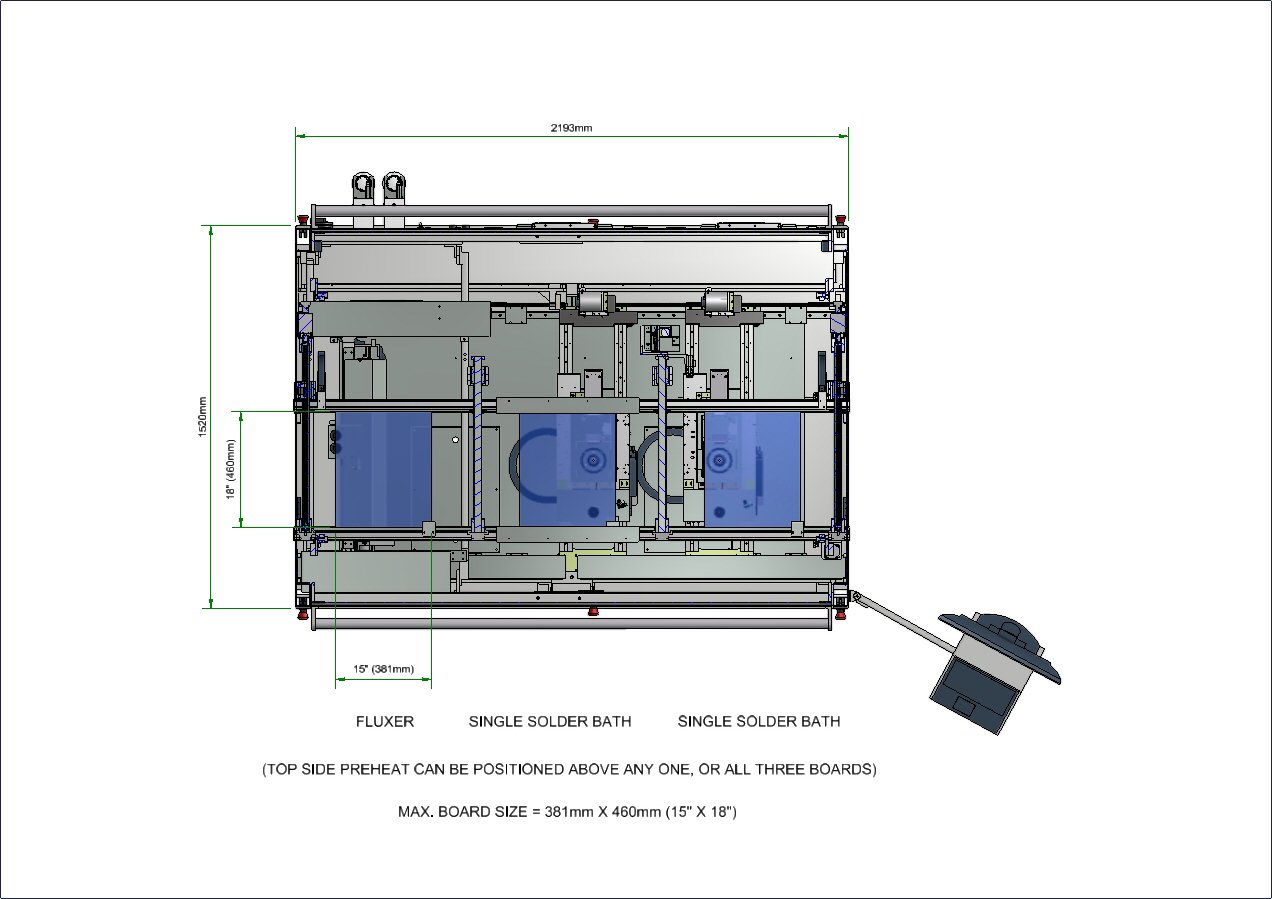

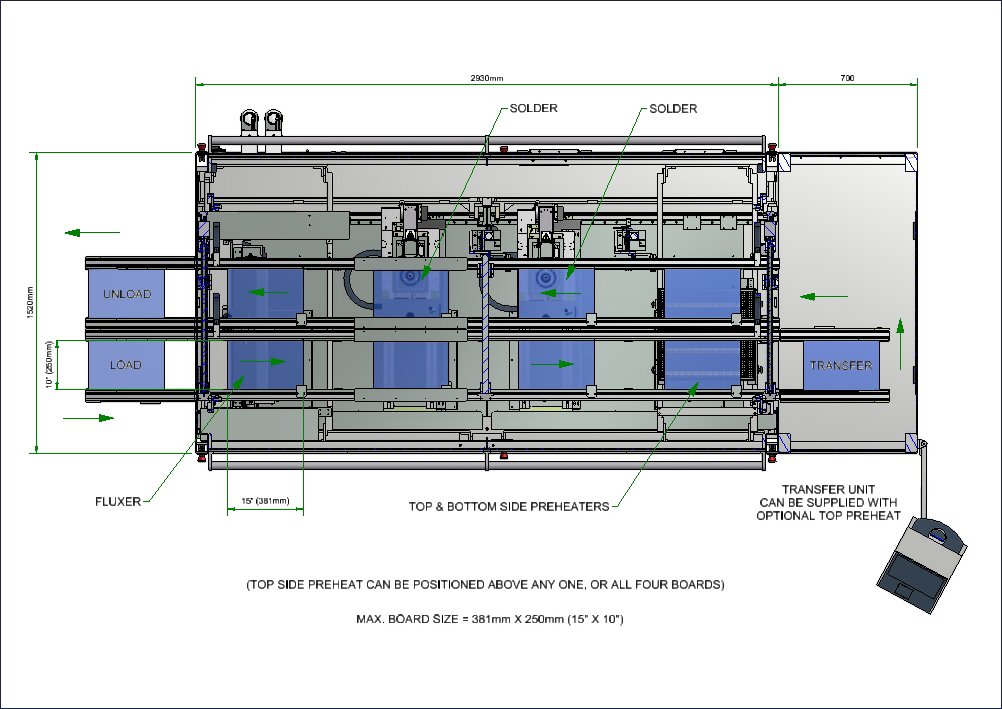

Fusion Compact

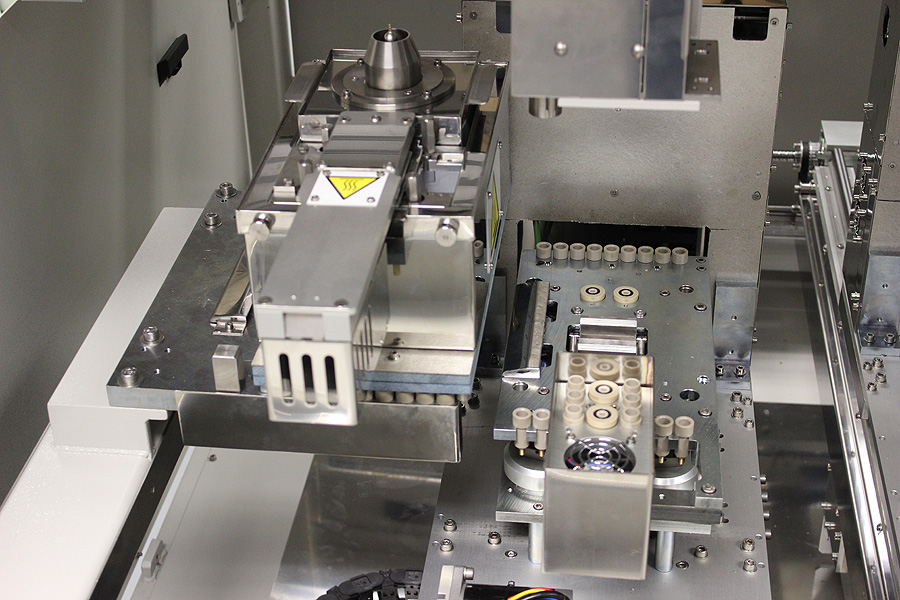

The three-station cell Fusion 3 Compact – fluxer, pre-heat, solder – can be configured to handle PCBs up to 381mm x 430mm, with a larger PCB handling size available upon request. For increased soldering capability, this same unit can be configured as fluxer/pre-heat and two solder modules.

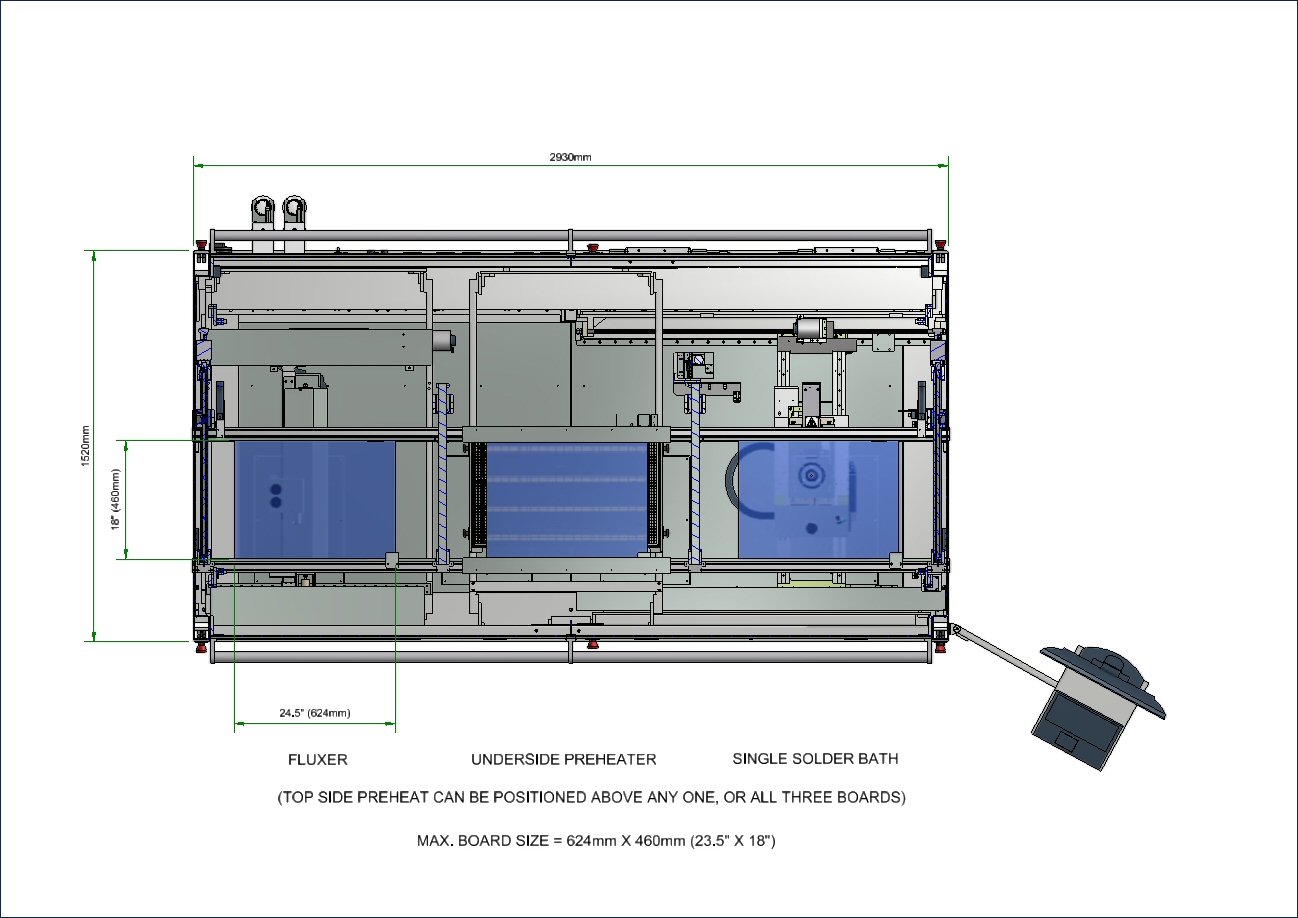

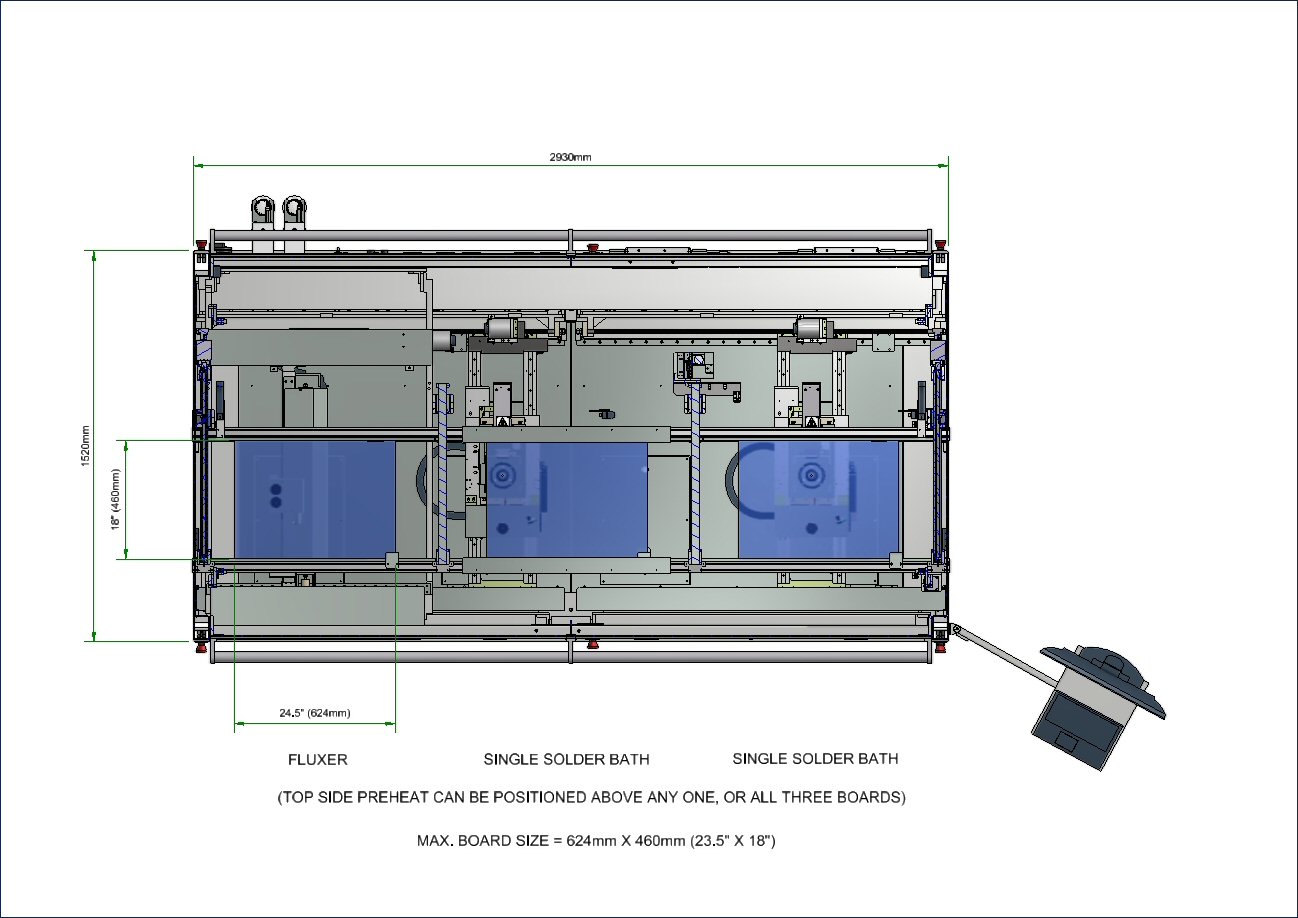

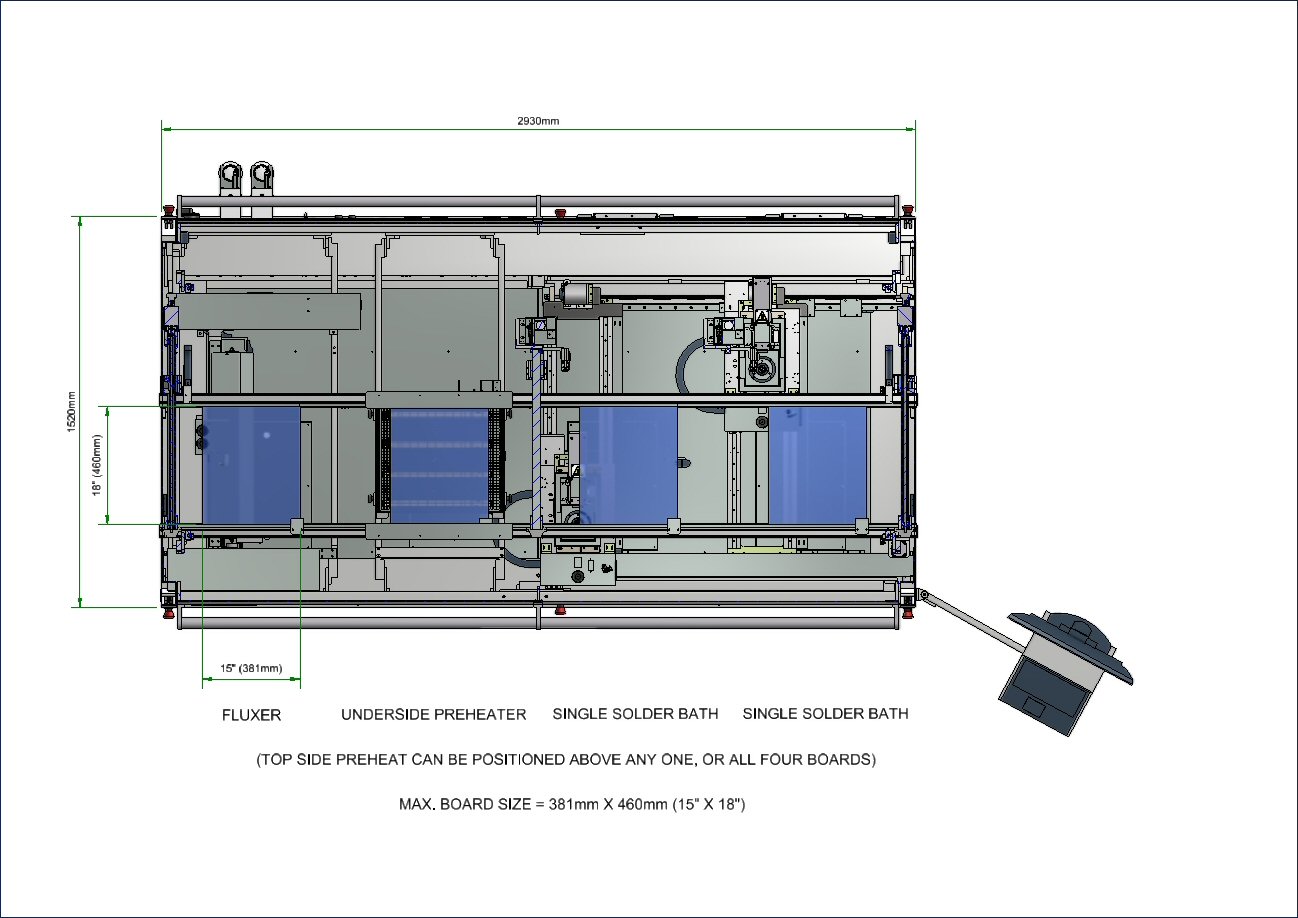

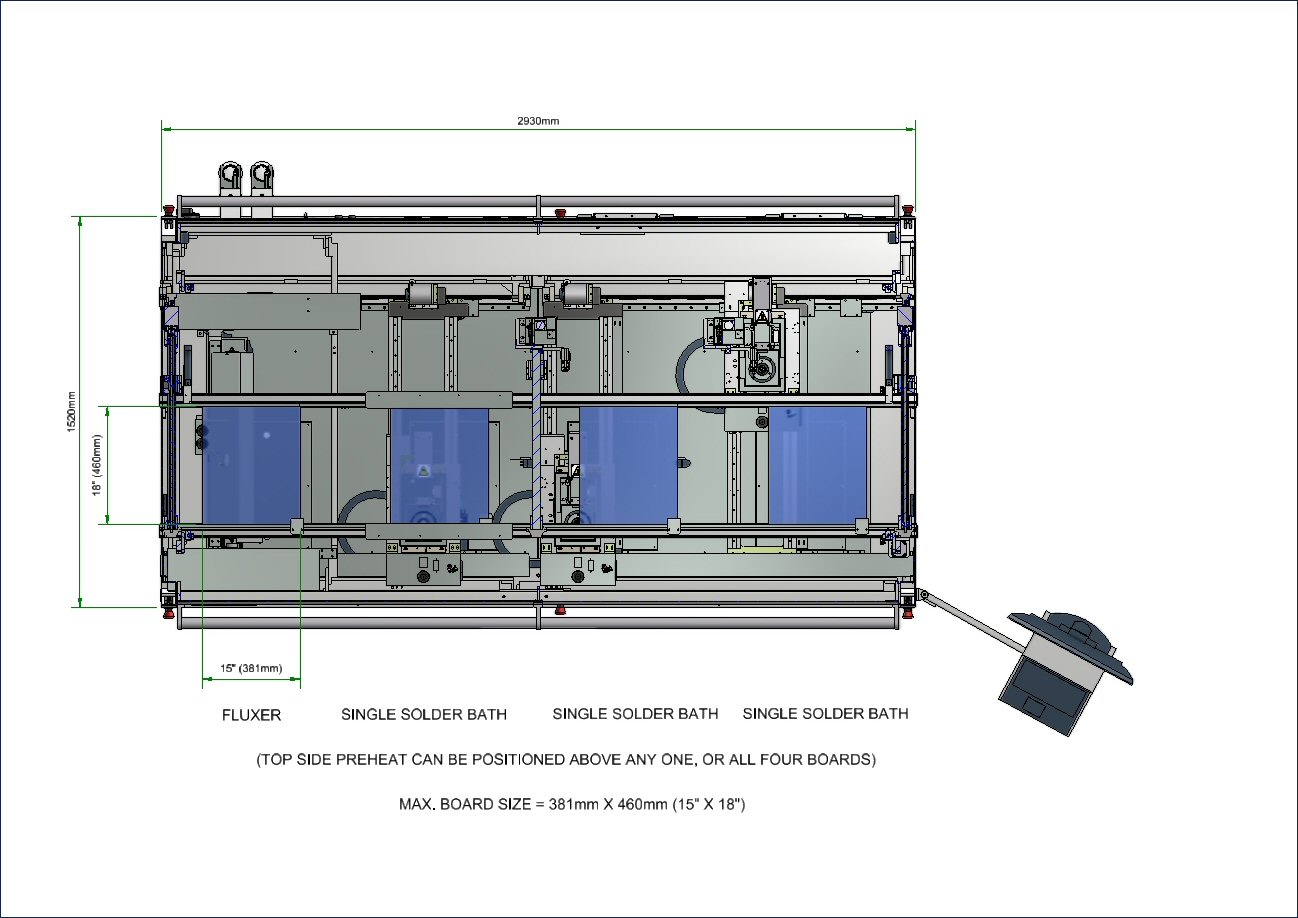

Fusion Standard

The standard four-station cell Fusion 4 – fluxer, pre-heat, solder, solder – can be configured to handle PCBs up to 381mm x 430mm, with a larger PCB handling size available upon request. For high-speed applications, this same unit can be configured as fluxer/pre-heat and up to three solder modules with as many as five heater options.

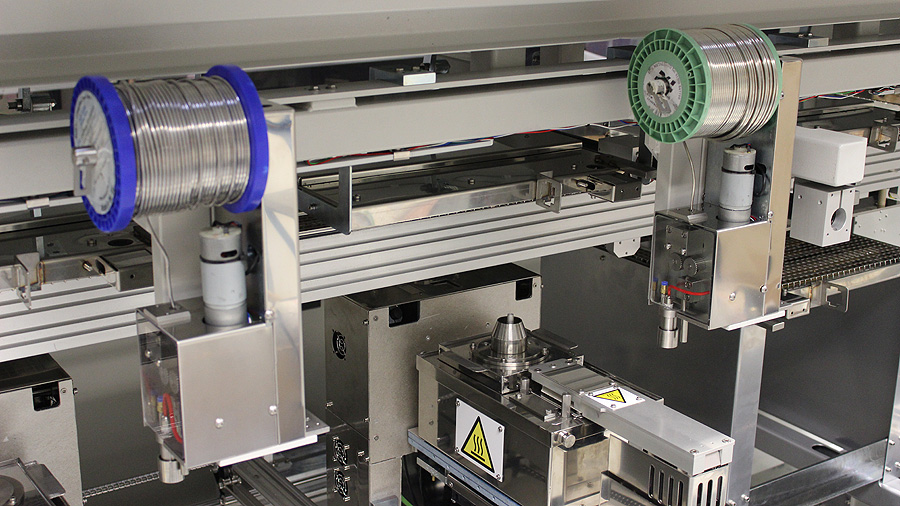

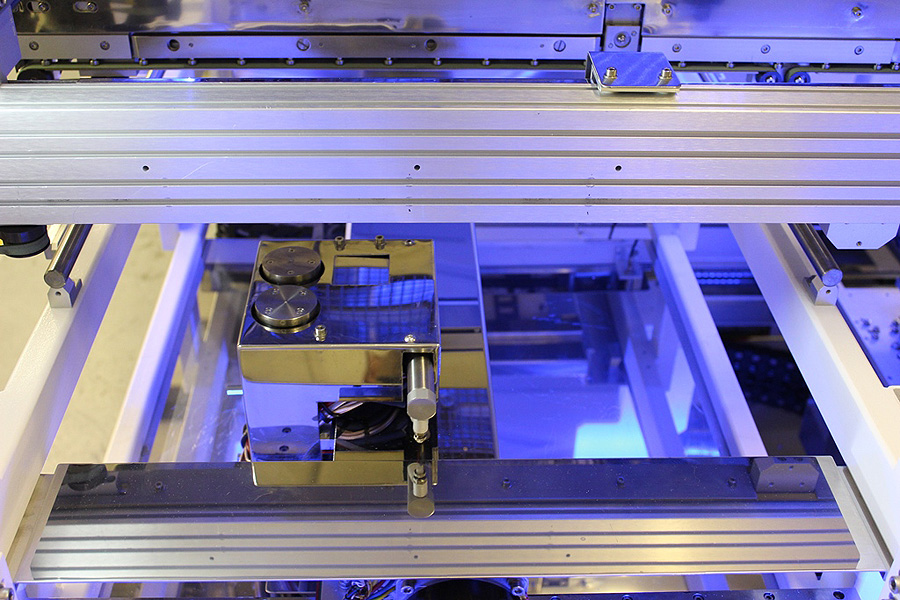

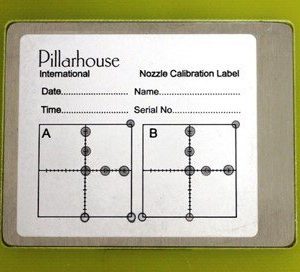

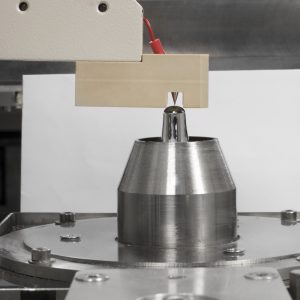

Each Orissa Fusion solder cell can be configured with any of the currently available Pillarhouse solder technologies: custom-dip, multi-dip, Jet-Wave and single point AP down to the patented 1.5mm micronozzle.

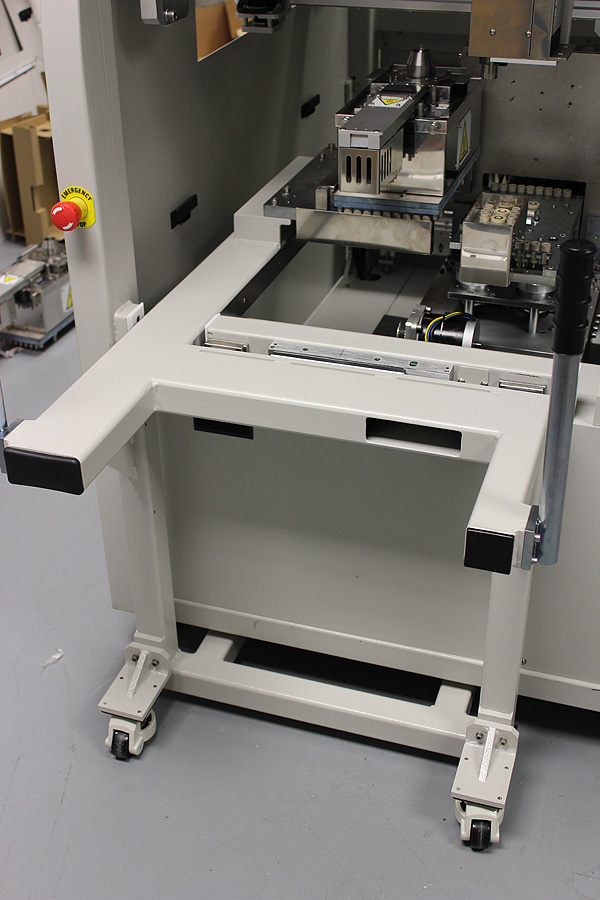

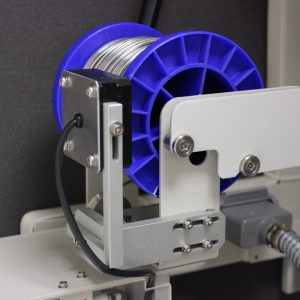

Easy, rapid non-contact solder pot changeover is facilitated via the optional heated pot exchange trolley.

For visual information about our Orissa Fusion, please visit our YouTube channel’s video here: Pillarhouse Orissa Fusion – YouTube

For more information about Pillarhouse International’s other in-line selective soldering systems, please visit: Selective Soldering – In-Line – Pillarhouse International