Description

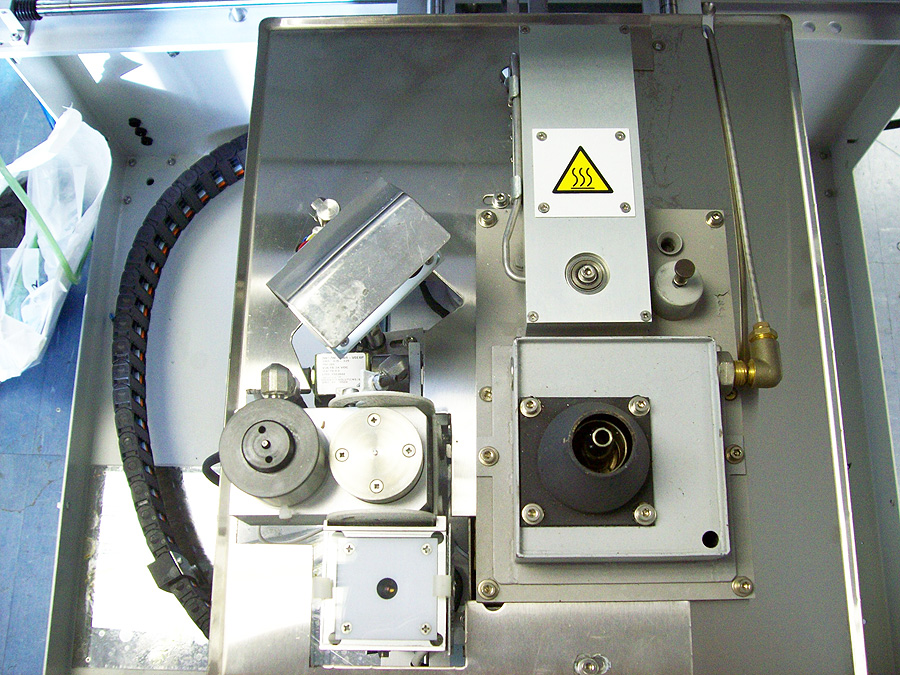

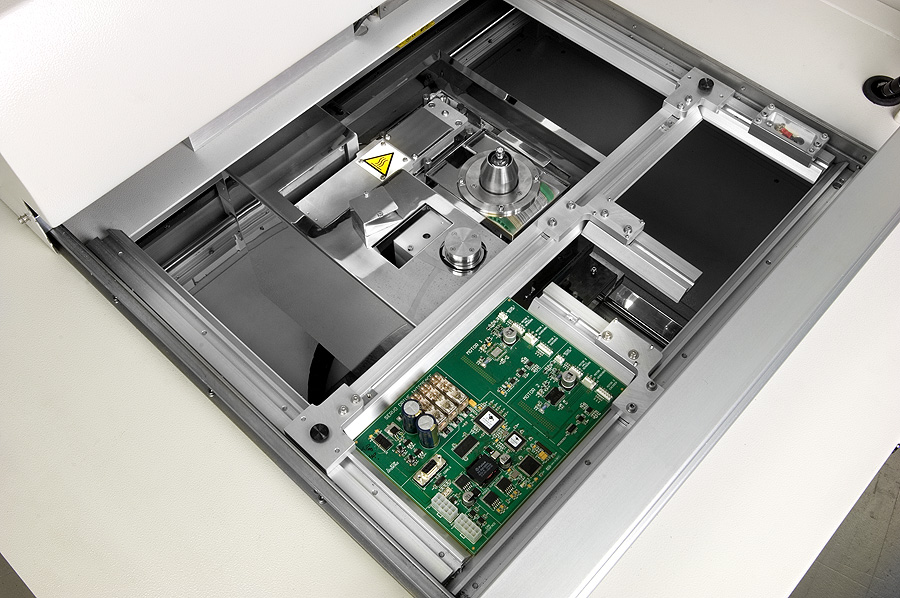

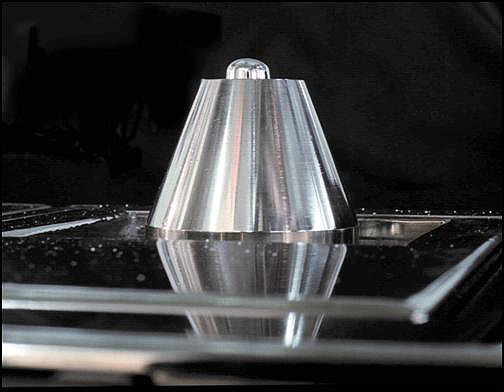

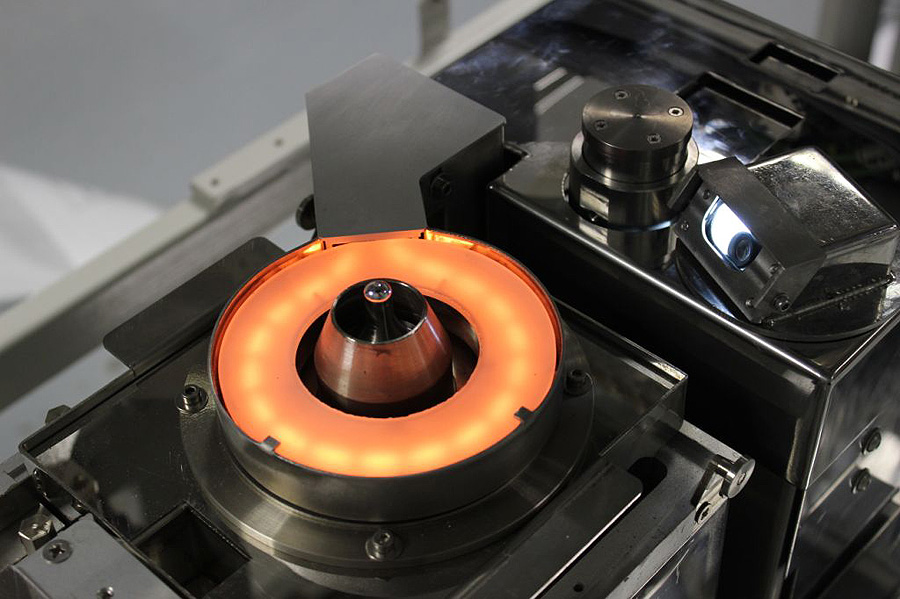

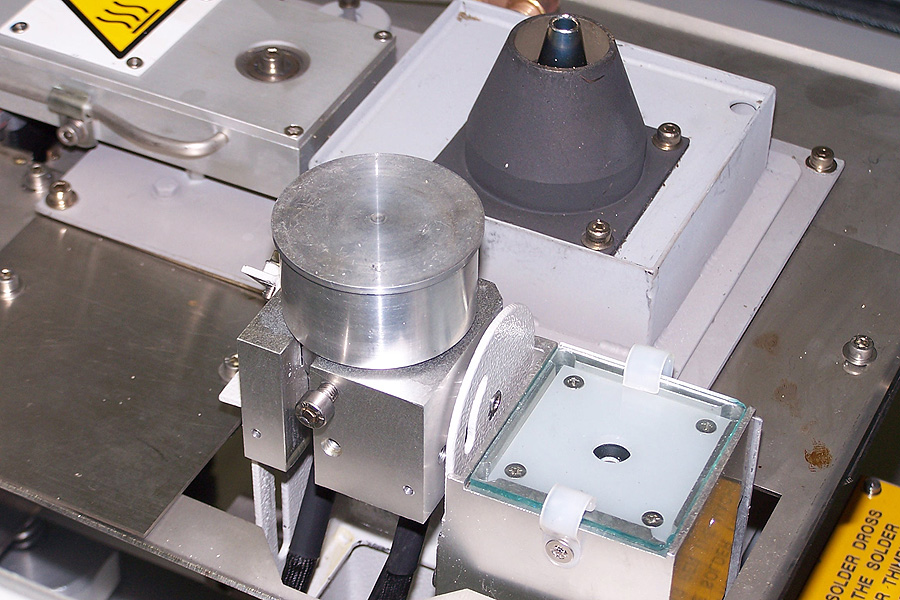

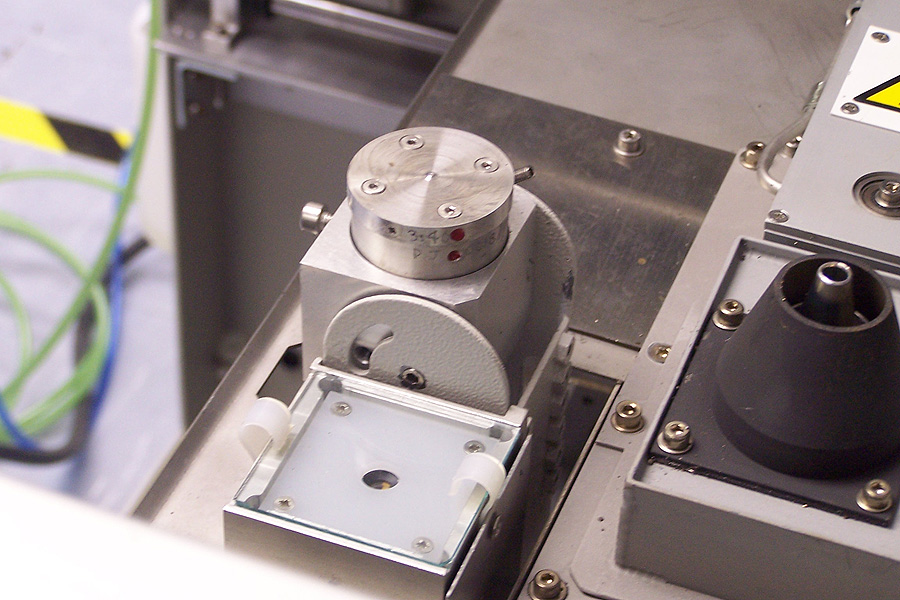

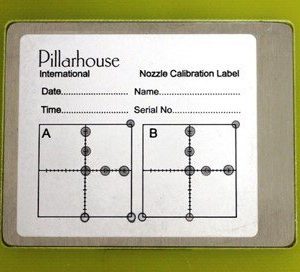

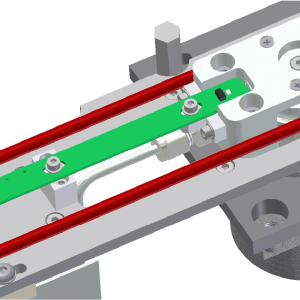

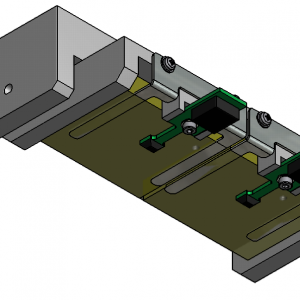

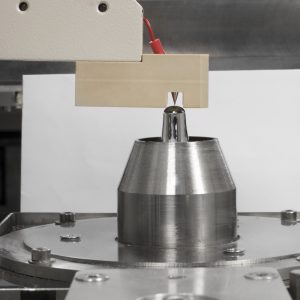

As part of the entry-level philosophy for the Jade MKII, a low maintenance solder bath and pump mechanism has been developed which moves in three axes of movement whilst not limiting access to the PCB. Solder is applied using proven technology through our AP nozzle design or custom specialised nozzles, incorporating patented spiral solder return-to-bath technology offering reduced solder balling potential.

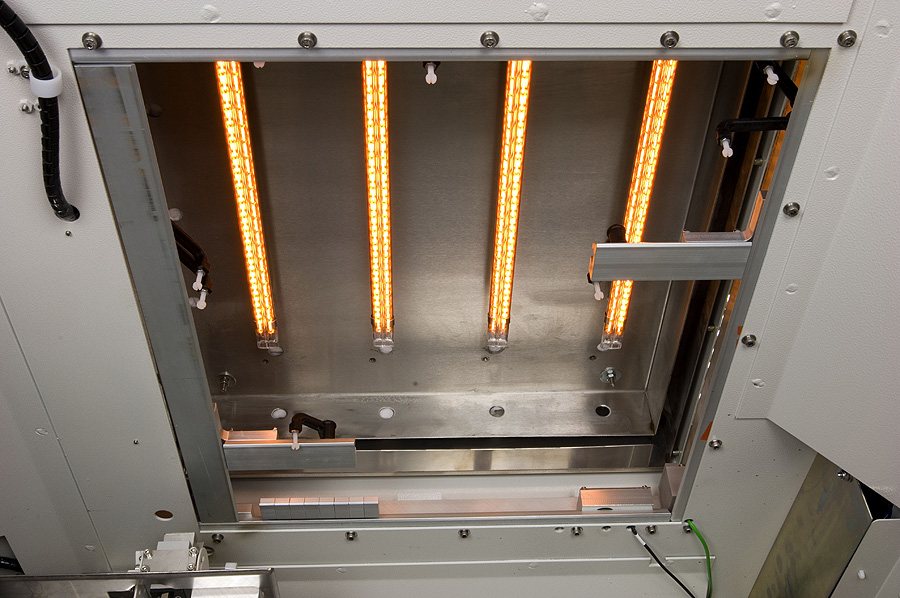

As with all Pillarhouse systems, the soldering process is enhanced by a hot Nitrogen curtain which provides an inert atmosphere. This method of soldering also assists in the prevention of oxidisation and provides a local pre-heat to the joint, thus reducing thermal shock to localised components.

The Jade MKII is controlled by a PC through our next generation PillarCOMMX software, a Windows® based ‘Point & Click’ interface with PCB image display. Additionally, our PillarPAD offline package allows the operator to produce programs independently from the machine using Gerber data.

For visual information about our Jade MKII, please visit our YouTube channel’s video here: Pillarhouse Jade Mk II – YouTube

For more information about Pillarhouse International’s other handload selective soldering systems, please visit: Selective Soldering – Handload – Pillarhouse International