Description

Industry 4.0 (Smart Factory 1.0) is the use of automation and data exchange in manufacturing technologies. It includes cyber-physical systems, the Internet of Things and cloud computing . Industry 4.0 creates what has been called a “smart factory”. Within the modular structured smart factories, cyber-physical systems monitor physical processes, create a virtual copy of the physical world and make decentralized decisions. Over the Internet of Things, cyber-physical systems communicate and cooperate with each other and with humans in real time, and via the Internet of Services, both internal and cross-organizational services are offered and used by participants of the value chain.

The Pillarhouse Smart Factory 1.0 implementation allows a customer to monitor the performance of all their Pillarhouse Selective Soldering Systems . This can be across a single production line, a production facility or even across a worldwide network of facilities.

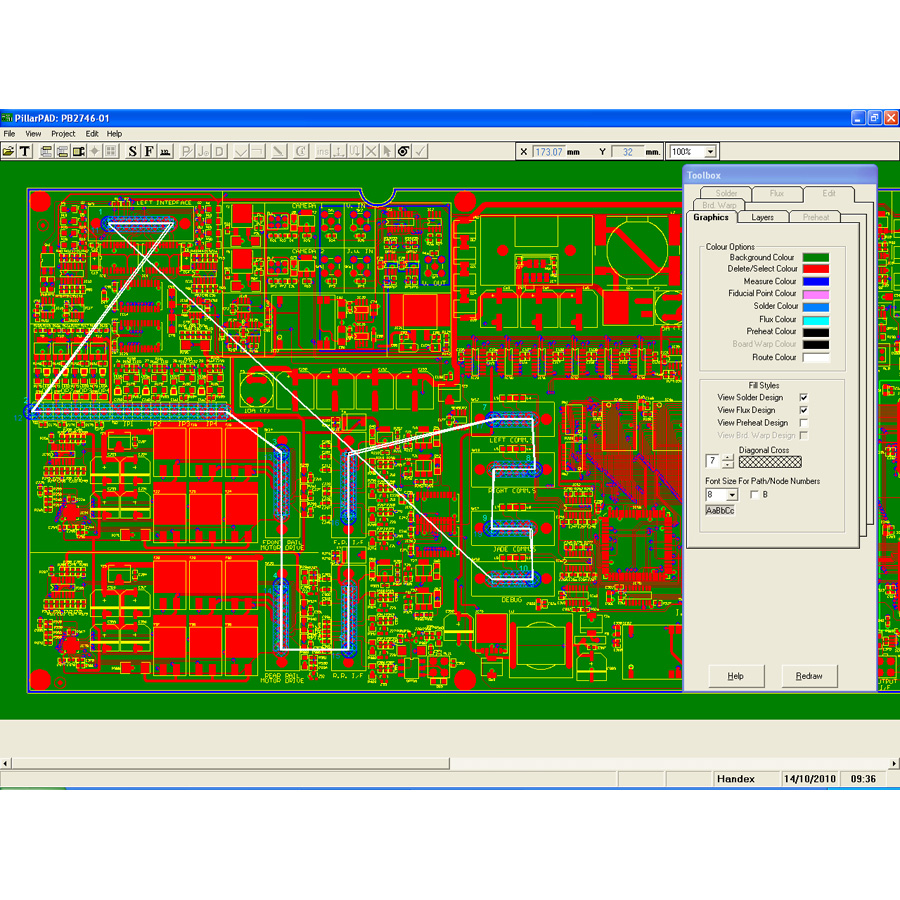

The Pillarhouse implementation is based on the outline for IPC standard 2-17 (Data Connected Factory) . It uses a series of data and event messages to record operations within the Selective Soldering System. These range from ‘system initialized’ through ‘system in maintenance mode’ to an ‘item completed’ report. These messages are packaged using the JSON standard and are then transmitted to a Message Broker using MSMQ , MQTT or REST message protocols.

Using Smart Factory Output

When a predefined event occurs or a piece of informational data is ready to be output, then it is packaged and transmitted to a Message Broker. This Message Broker receives and processes the message. This processing can range from a simple acknowledge of the message through to the decoding of each field of the message and then storing this data in a database. This data can then be used to generate reports or statuses for each Pillarhouse machine or production line. Depending on the nature of the end-user reports could vary between notifications of maintenance requirements and errors to line maintenance crews; through to production line utilisation reports for Production Management teams. As the data is stored in a database it can be processed in many ways and allows full traceability of produced items and also the performance of the Selective Soldering Systems.

Smart Factory Options

Pillarhouse offer a number of different ways of implementing a Smart Factory solution in your facility.

Message Only Output.

If your company/facility already has a Smart Factory implementation, or is considering a multi-vendor solution, then the Pillarhouse equipment can be configured to send all messages to a central Message Broker using any of the pre-defined protocols. Pillarhouse can supply details of all available messages.

Pillarhouse Broker

Pillarhouse offers a complete Message Broker/Reporting package. This consists of a Server PC configured run a Message Broker software package and a Website. The broker collects and stores all incoming messages, whilst the website provides basic machine reports, for each connected Pillarhouse system.

Pillarhouse Hosted Cloud-based Broker

This option is similar to the Pillarhouse Broker package, but uses the Pillarhouse Cloud storage to store all the data and generate web-based reports. If the cloud option is selected then the customer is provided with their own access portal to ensure security is maintained.

Please fill in your details below to be taken to our brochure downloads page.