Enhancing the soldering process

Enhancing the soldering process

Pre-heating is used to create an optimal environment for the soldering of a PCB. By heating the PCB, this helps to activate the flux, improves solder joint quality, and reduces the risk of component thermal shock. This method assists solder pull through on multi-layer PCBs and components with significant ground planes.

With the introduction of lead-free solders, it has become almost essential to have some form of pre-heating. Closed-loop control can be used for precise and reliable heating and provides added confidence to your process.

Pre-Heater Technologies

Selective Hot Nitrogen

By heating a flow of Nitrogen, the soldering systems can pre-heat a localised area of the PCB whilst maintaining the inert atmosphere.

By heating a flow of Nitrogen, the soldering systems can pre-heat a localised area of the PCB whilst maintaining the inert atmosphere.

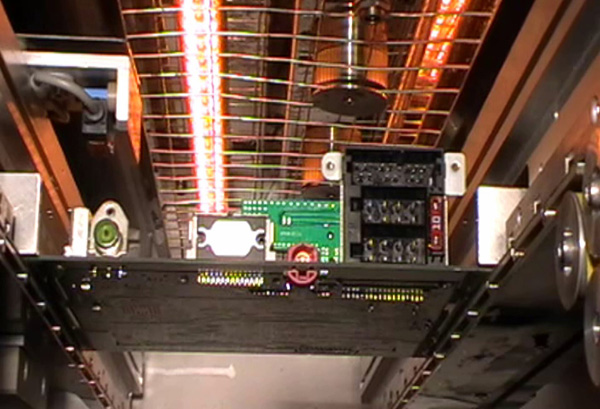

Top Side Infrared Pre-Heat

By using fast response infrared lamps, Pillarhouse can pre-heat the PCB before fluxing, during fluxing and/or after fluxing.

By using fast response infrared lamps, Pillarhouse can pre-heat the PCB before fluxing, during fluxing and/or after fluxing.

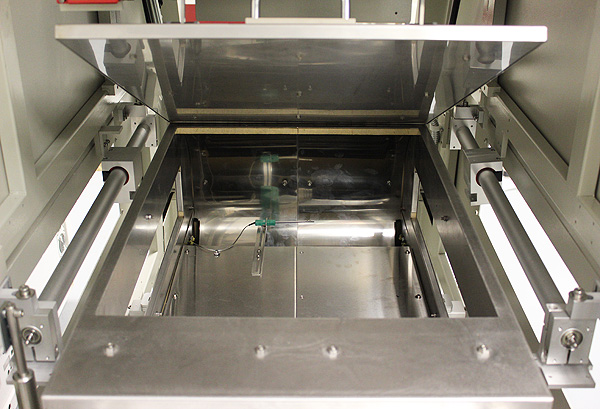

Bottom Side Infrared Pre-Heat

By using fast response infrared lamps, Pillarhouse can pre-heat the PCB after fluxing.

By using fast response infrared lamps, Pillarhouse can pre-heat the PCB after fluxing.

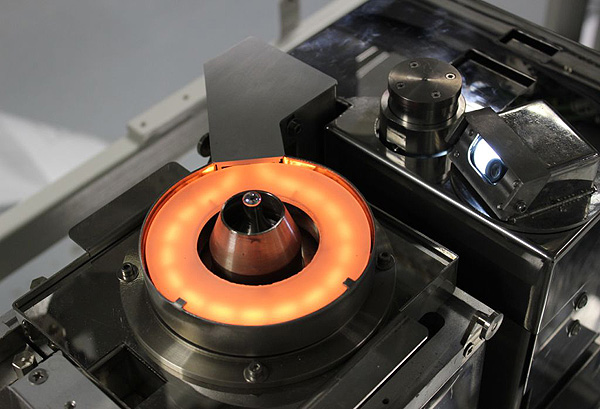

Bottom Side Ring Infrared Pre-Heat

By using a fast response ring infrared lamp, Pillarhouse can pre-heat the PCB during the soldering cycle.

By using a fast response ring infrared lamp, Pillarhouse can pre-heat the PCB during the soldering cycle.

Top and Bottom Side Infrared Pre-Heat

Allows simultaneous heating of the top and bottom side, where the application dictates for complex or heavy multi-layer PCBs.

Convection

This additional source of pre-heating offers the ability to ‘soak’ PCBs for prolonged periods with minimal risk of scorching and further reducing the possibility of thermal shock to components. Convection pre-heat can be particularly beneficial when processing large multi-layer PCBs when cycle time is not critical e.g. back planes, aerospace applications etc.

This additional source of pre-heating offers the ability to ‘soak’ PCBs for prolonged periods with minimal risk of scorching and further reducing the possibility of thermal shock to components. Convection pre-heat can be particularly beneficial when processing large multi-layer PCBs when cycle time is not critical e.g. back planes, aerospace applications etc.

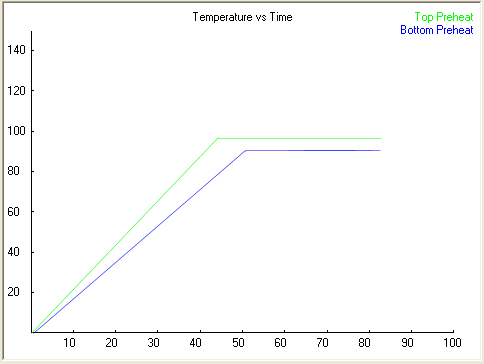

Pre-Heater Control

Closed-loop control

Pyrometer based, closed loop control system.

Pyrometer based, closed loop control system.

- Adjustable position to monitor PCB, or specified area (component).

- Monitors target temperature and adjusts the operating power automatically.

- Applies to both top side & bottom side pre-heat systems.

- Real-time display of target temperature.

Open-loop control

- Uses operator set values for power and exposure time.

- Applies to both top side & bottom side pre-heat systems.